- Home Page

- Company Profile

-

Our Products

- Fully Automatic Can Body Welder

- Body Blank Transfer System

- Industrial Machines

- Production line of CNC punch press

- Multi station combined machine for special shaped

- Powder spraying machine

- Slitter Machine

- Drying Oven

- Sealing Machines

- Can Welding Machines

- Welding Seam Powder Coating

- Full Automatic Powder Coating Machine

- Leak tester for food can/aerosol can/milk powder can/paint can

- Automatic CNC punching Machine

- High precise duplex gang slitter

- 45 Ton Automatic Press Machine

- CNC Automatic Sheet Press

- Industrial chiller

- Intelligent Powder Spraying Machine

- Series Electromagnetic Induction Dryer

- Combination Machines

- Contact Us

- Fully Automatic Can Body Welder

- Body Blank Transfer System

- Industrial Machines

- Production line of CNC punch press

- Multi station combined machine for special shaped

- Powder spraying machine

- Slitter Machine

- Drying Oven

- Sealing Machines

- Can Welding Machines

- Welding Seam Powder Coating

- Full Automatic Powder Coating Machine

- Leak tester for food can/aerosol can/milk powder can/paint can

- Automatic CNC punching Machine

- High precise duplex gang slitter

- 45 Ton Automatic Press Machine

- CNC Automatic Sheet Press

- Industrial chiller

- Intelligent Powder Spraying Machine

- Series Electromagnetic Induction Dryer

- Combination Machines

Fully Automatic Tuna Can Body Welding Machine

X

Product Description

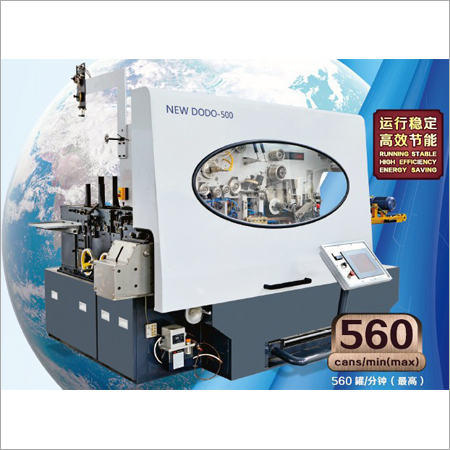

Fully Automatic Can Body Welding machine (NEW DODO-500)

Main Feature:

- Equipped with the most advanced man-computer interface device, the whole operation can be made on the touch screen.

- Equipped with the servo motor controlling system, the controlling system runs without noise.

- Equipped with electronic static adjustable inverter power supply.

- Equipped with failure self-detected system,system alarms automatically and provides the solution proposal

- Equipped with copper wire profiling roller in ceramic,improve the insulation

- Equipped with the very durable ceramic unit on the can conveying system to reduce wear out.

- Equipped with the standard mercury lower welding roller, the nonmercury welding roller also available as a option.

- Lower welding arm available for both internal powder coating and internal liquid spraying coating with Nordson pump.

- Induction drying oven and gas drying oven available for your choice.

Technical Parameter:

| Type | New DODO-500 |

| Welding Speed | 70m/min(max) |

| Production capacity | 500cans/min. |

| Stitch Range | 0.5-0.9mm |

| Overlap | 0.25-0.4mm |

| Can diameter | 202(52mm)-401(99mm) |

| Canbody height | 60-150mm |

| Can body material | Tinplate, Ni Plate |

| Material thickness | 0.14-0.28mm |

| Tin coating | Tin 5#-100# |

| Temper | T2.5-DR8 |

| Copper wire diameter | 1.24mm-1.38mm |

| Power supply | 3 phases, voltage 380V |

| Frequency 50Hz, power consumption 60kw | |

| Welding frequency | 200-750Hz |

| Chilling water | 500kpa, 12-18°c, 20L/min |

| Compressed air | 500kpa, 800L/min |

| Dimension | 3000 X 3200X 2200mm |

OEM service is available for your special requirement.

NEW DODO products series are manufactured under the latest technology version, specifications are subject to change without notification.

Special feature: very high speed welder for can makers to improve production capacity

The machine adopts the new style Schneider programmable controller (PLC) and communication system from Schneider. Use the Schneider's inverter as central controlling parts for the main electronic components; the Schneider most advanced touch screen operation system is adopted as well. And the group technology is used to realize the intelligent control.

Chilling system: The machine adopts the internal auto cycling chilling system,equipped with the chiller and water flux pressure protective device.

The machine consists of auto can rounding equipments, auto copper wire tracing,calling back and cutting devices; double fingers can conveying table; static digital adjustable frequency inverting power supply devices; vacuum trigger from swiss; and double sheets detecting devices from Japan's Keyence,etc. The machine is equipped with inside and outside Nitrogen protective devices, caliber fixer, and calibrating devices.

The main electronic components, pneumatic devices and mechanic transmitting equipments are from the international well-known manufacturers, e.g Schneider , omRon, etc.

Other Products in 'Can Welding Machines' category

SHANTOU XINQING CANNERY MACHINERY CO.,LTD.

7th Section, Jinyuan Industrial Area, Shantou - 515041, Guangdong, China

Phone :View Number

Fax :View Number

|

|

|

|

|

SHANTOU XINQING CANNERY MACHINERY CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |